Nitrogen Snuffing System

Nitrogen snuffing system. Nitrogen sounds like the obvious choice because it eliminates the oxidizing agent oxygen. About CO2 snuffing system skid. On Site Gas Systems Nitrogen Generators can provide a flow of up to 999995 nitrogen simply with the press of a button.

System except for the subsequent effect that it might produce. Nitrogen SystemEngineered for a wide range of applications Room size and combustible material requirements determine the system design. Fixed water sprays.

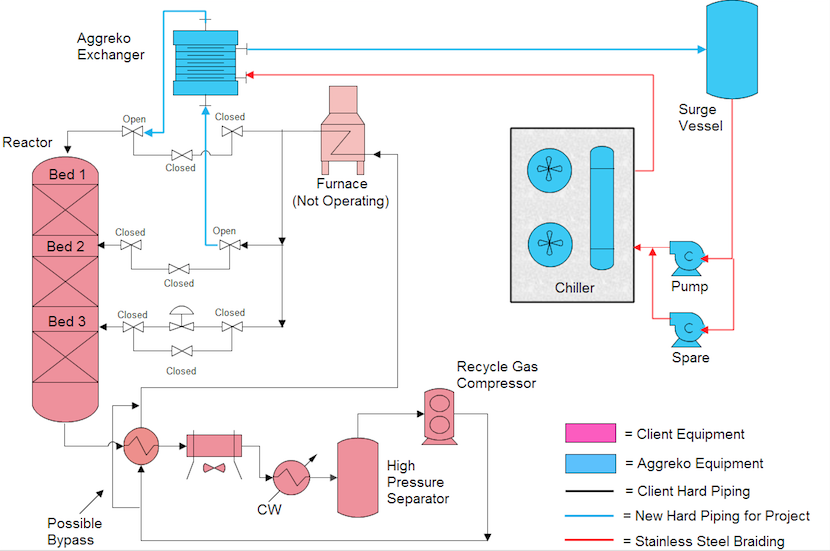

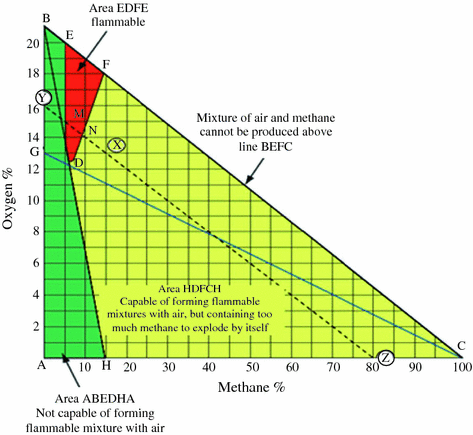

In the right situation however steam CO2 or nitrogen snuffing systems may be able to be used to displace the O2 and create a relatively inert atmosphere. As an inert gas medium nitrogen is the purest and thereby the preferred solution for applications where cargo contamination could be an issue. Hi everyone I need your help on finding some standards or good engineering practices about the flow-rate needed for nitrogen no steam is available emergency snuffing of a furnace.

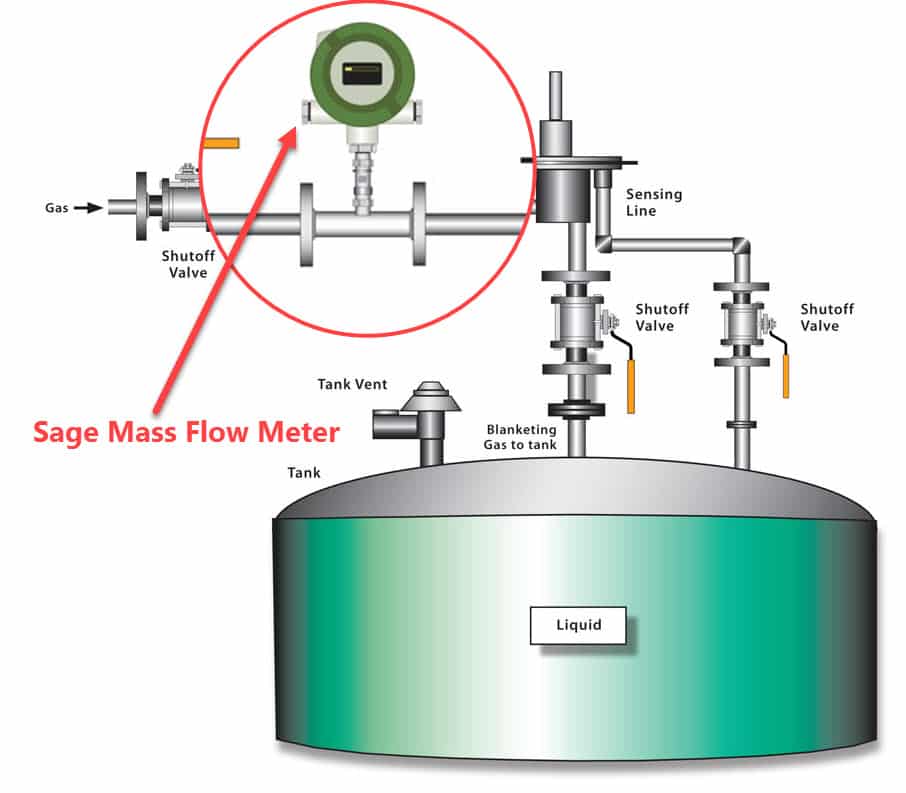

In-built engineered extinguishing systems. Installation of a nitrogen snuffing system. An inerting system decreases the probability of combustion of flammable materials stored in a confined space especially a fuel tank by maintaining a chemically non-reactive or inert gas such as nitrogen in such a space.

The engineered design selects appropriate pipe sizes and nozzles to ensure effective suppression. The NFPA snuffing steam rate stated in the standard results in a large steam rate being fed to sulfur tanks and sulfur pits that typically have a low design pressure. Nitrogen fire suppression systems utilize pure Nitrogen which is naturally occurring inert gas present in the atmosphere.

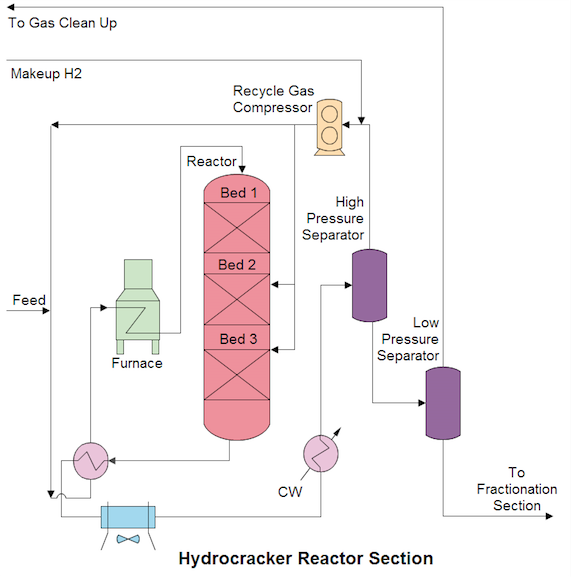

Nitrogen will still be required in order to purge the flare stack downstream of the Fast Opening Valves that are normally installed in the main headers as part of flare recovery projects. Chain reactions in a combustion event can rapidly spread a fire. Nitrogen snuffing systems.

The code specifies an inert gas system. Nitrogen operates as a fire suppressant by reducing the oxygen.

Fixed water sprays.

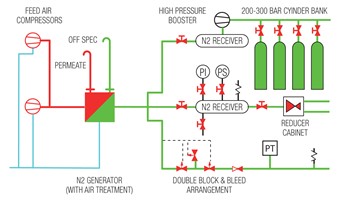

On Site Gas Systems Nitrogen Generators can provide a flow of up to 999995 nitrogen simply with the press of a button. Inerted fuel tanks may be used on land or aboard ships or aircraft. Each UL and CE-certified commercial nitrogen generator is equipped with an oxygen analyzer to instantly read purity level. Our Hi-low Pressure Pilot System can effectively manage and control the process shutdown for flowlines. Correct location of nitrogen blanketing on the vent line to the thermal oxidizer can reduce vapor losses but in some cases it may be necessary to sweep the vapor space eg. Whilst these mitigate measures have been effective at minimising the duration of the fires in subsequent events the cause of each ignition remains unknown. Deluge foam and water mist systems. Nitrogen will still be required in order to purge the flare stack downstream of the Fast Opening Valves that are normally installed in the main headers as part of flare recovery projects. Chain reactions in a combustion event can rapidly spread a fire.

Nitrogen fire suppression systems utilize pure Nitrogen which is naturally occurring inert gas present in the atmosphere. Nitrogen SystemEngineered for a wide range of applications Room size and combustible material requirements determine the system design. Inerted fuel tanks may be used on land or aboard ships or aircraft. On Site Gas Systems Nitrogen Generators can provide a flow of up to 999995 nitrogen simply with the press of a button. Each UL and CE-certified commercial nitrogen generator is equipped with an oxygen analyzer to instantly read purity level. The code specifies an inert gas system. Supress fires and ensure safety protocols are met with our effective Nitrogen Snuffing System.

Post a Comment for "Nitrogen Snuffing System"